Protein Bioproduction

Dr. Park Co., Ltd., has successfully produced many proteins based on more than 10 years of diverse experience in customized protein

production and is a leader in recombinant protein production that is difficult for expression.

We provide large amounts of protein expression and purification services from low doses using Dr. Park’s own system at a low price.

Dr. Park provides the most advanced high throughput protein production platform based on the knowledge and how-how of the best

protein production experts. Therefore, Dr. Park builds all systems to meet or surpass the customer’s requirements through high level

production platform.

Dr. Park is striving to provide customers with the highest purity protein production platform. Our experts have developed the latest system

to overcome the limitations of producing specialized proteins for experimentation or pharmaceuticals by implementing the optimal

protein expression system.

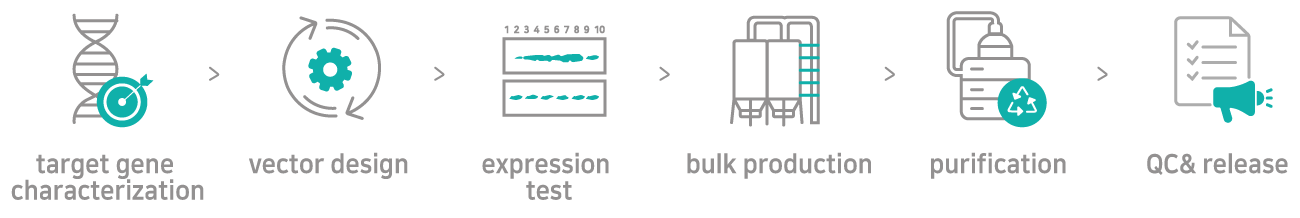

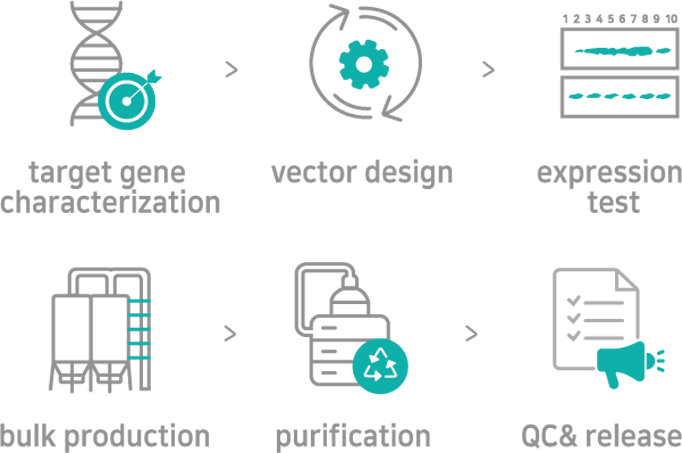

These systems are provided to customers by establishing customized recombinant protein expression conditions for each condition based

on an accurate understanding of each given protein. In line with the needs of the customers, synthetic gene, customized expression vector

production, initial protein production, and large protein expression system in the fermentor and bioreactor are being composed.

We are building the best system quickly produce multiple recombinant proteins at an inexpensive price on those expressive proteins such

as multiple enzyme and cytokine. Our services include all stages of using large-capacity bioreactors and fermentor, including gene

synthesis and production of expression vectors.

Dr. Park Laboratory produces recombinant proteins using various systems, including E.coli and CHO cells, and provides proteins at the GMP and non-GMP levels

I EXPRESSION SYSTEMS

Bacterial

Bacterial

Mammalian

Mammalian

The protein produced by Dr. Park is produced using adherent HEK 293 using the Cell Factory system or using single-use bioreactors 250L

to produce proteins using suspension HEK293 and CHO under serum free conditions.

In addition, when using E.coli, protein is produced using fermentors ranging from at least 5 liters to a maximum of 100 liters.

As mentioned earlier, we are building a cell culture system with a minimum of 5 liters to a maximum of 250 liters, providing customers

with the desired amount of production faster than anyone else.

High throughput Commercial Protein facility